Wearing Parts For Cigarette Making Machine

The wearing parts of cigarette machines are essential components that ensure the smooth and efficient operation of cigarette manufacturing equipment. These parts endure high levels of stress and friction during production, making them susceptible to wear. Our high-quality wearring parts are meticulously designed to withstand these demanding conditions, offering durability, reliability, and optimal performance.

Key Features:

1. High Durability:

Our wear-prone parts are made from premium materials such as hardened steel, carbide, and advanced polymers, ensuring long-lasting performance. They are resistant to wear, corrosion, and mechanical stress, guaranteeing an extended service life.

2. Precision Engineering:

Each component is manufactured to strict tolerances, ensuring a perfect fit and seamless integration with your cigarette machine. This precision reduces downtime and maintenance costs.

3. Enhanced Performance:

Our wear-prone parts are designed to maintain consistent performance, even under high-speed operations. This ensures uninterrupted production and high-quality output.

4. Easy Replacement:

Our wear-prone parts are designed for quick and easy installation, minimizing machine downtime. Clear instructions and compatibility with major cigarette machine brands make replacements straightforward.

5. Cost-Effective:

By reducing replacement frequency and minimizing machine downtime, our wear-prone parts provide a cost-effective solution for maintaining your cigarette production line.

6. Product Range:

Our comprehensive range of wear-prone parts includes but is not limited to:

Regular Cutting Blades: Includes long knives and circular blades, used for cutting cigarette rods or filter rods.

Nylon Tape/Steel Suction Tape: conveying tobacco strands.

Garniture tape: Transports tobacco strands and cigarette paper.

Cigarette Tray: Used for storing cigarettes

Filter Rod Tray: Serves as a temporary storage container for filter rods, ensuring a continuous supply during production.

Alloy Tipping Knife: Mainly used for cutting hollow filter rods.

Spring Band:The spring belt and the suction steel belt are used together to complete the function of conveying tobacco

Collector Tube: to lift the tobacco strands by airflow, facilitating their absorption onto the steel/nylon suction belt.

Regular Gringing wheel:Make the long knife sharp

Alloy Gringing wheel:Make the circular blade sharp

Tongue: Evenly feeds tobacco strands into the cigarette paper, ensuring uniform distribution. It also adjusts the position and pressure to control the tightness and diameter of the cigarette, ensuring consistent appearance and burning performance.

Box Ejector:

Used to secure and support cigarette boxes, ensuring they remain stable during production and preventing misalignment or tilting.

It also ensures accurate positioning of the cigarette box during packaging, allowing materials like aluminum foil or cellophane to precisely wrap the box.

Needle Plate:

Combs tobacco strands through its needle structure to ensure even distribution, preventing clumping or tangling, and ensuring uniform feeding into the cigarette paper. It also regulates the flow of tobacco into the cigarette machine, ensuring a stable supply and avoiding excess or shortage. Additionally, during the combing process, the needle plate removes impurities and short fibers, improving tobacco quality.

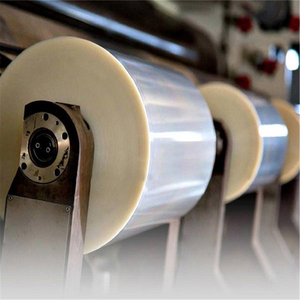

Belt:

The belt is used to transport materials such as tobacco strands and cigarette sticks, ensuring smooth transfer between different stages of production.

It also ensures synchronized operation of components, maintaining a coordinated production process and preventing disconnections or blockages.

Our wear-prone parts are suitable for various types of cigarette machines, including:

- Making Machines:Used for forming and shaping cigarettes.

- Packaging Machines: Used for packing cigarettes into boxes and cartons.

- Filter Tip Attachers: Used for attaching filters to cigarettes.

Why Choose Us?

- Expertise: With years of industry experience, we understand the unique demands of cigarette production.

- Quality Assurance:Rigorous testing and quality control processes ensure every part meets the highest standards.

- Customer Support: Our dedicated support team assists with product selection, installation, and troubleshooting.

Investing in high-quality wear-prone parts for your cigarette machines is crucial for maintaining productivity and ensuring the longevity of your equipment. Our wear-prone parts perfectly combine durability, precision, and performance, making them the ideal choice for your cigarette manufacturing needs. Contact us today to learn more about our products and how we can help optimize your production line.