Key Components and Process Flow of Cigarette Making Machines

Cigarette making machines play a crucial role in the tobacco industry by automating the process of manufacturing cigarettes. These machines are designed to efficiently produce high volumes of cigarettes with consistent quality and precision. They consist of several key components and follow a well-defined process flow to transform tobacco leaves into finished cigarettes. In this article, we will explore the key components of cigarette making machines and the process flow involved in their operation.

Key Components of Cigarette Making Machines

Tobacco Feeder

The tobacco feeder is responsible for delivering the required amount of tobacco to the machine. It ensures a steady and controlled flow of tobacco leaves into the manufacturing process.

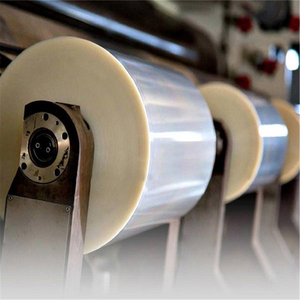

Garniture Tapes

Garniture tapes are continuously moving belts with precision-cut perforations. These tapes carry the tobacco and form it into a continuous rod known as a tobacco rod. Garniture tapes determine the cigarette's diameter, density, and overall quality.

Cigarette Paper Supply

Cigarette paper is supplied in the form of large reels. The paper supply system feeds the paper into the machine, and it is wrapped around the tobacco rod to form the cigarette tube.

Filter Attachment

Filter attachment is a crucial component that adds filters to the cigarette tubes. Filters are typically made of cellulose acetate and provide filtration and a means for the smoker to hold the cigarette.

Gluing Unit

The gluing unit applies a thin strip of adhesive to the paper to seal the cigarette tube. It ensures that the cigarette remains intact during smoking and maintains its structural integrity.

Cutting Mechanism

The cutting mechanism divides the continuous tobacco rod into individual cigarette lengths. It also trims excess paper and filters, ensuring the proper length and appearance of each cigarette.

Packaging System

Once the cigarettes are formed and cut, they are directed to the packaging system. This system wraps the cigarettes in packs, applies cellophane or foil wrapping, and adds any required labeling or branding.

Process Flow of Cigarette Making Machines

Tobacco Feeding: The tobacco leaves are fed into the machine through the tobacco feeder, which controls the flow rate to maintain consistency.

Formation of Tobacco Rod

The tobacco leaves are collected by the garniture tapes, which form them into a continuous rod. The garniture tapes shape the rod with the desired diameter and density.

Paper Wrapping

As the tobacco rod moves forward, the cigarette paper is supplied and wrapped around the tobacco rod, forming a tube.

Filter Attachment: Filters are added to the cigarette tubes using the filter attachment mechanism. The filters are attached at precise intervals, ensuring consistent quality across the production line.

Gluing and Cutting

The gluing unit applies adhesive to the paper, securing the tube shape. Simultaneously, the cutting mechanism divides the continuous tobacco rod into individual cigarette lengths. Excess paper and filters are trimmed, resulting in properly sized cigarettes.

Packaging

The finished cigarettes are directed to the packaging system, where they are wrapped in packs, often containing 20 or 25 cigarettes. The packs may undergo additional processes, such as foil wrapping or cellophane sealing, before labeling and branding are applied.

Factors

If you are referring to factors that influence the composition and characteristics of cigarettes, there are several key factors to consider:

Tobacco Type and Blend

The choice of tobacco type and the blending of different varieties significantly affect the flavor, aroma, and overall smoking experience of a cigarette. Different types of tobacco, such as Virginia, Burley, and Oriental, have distinct characteristics that contribute to the final product.

Curing and Fermentation

The process of curing and fermenting tobacco leaves plays a crucial role in developing their flavor and aroma. Different curing methods, such as air-curing, flue-curing, or sun-curing, can result in different tobacco profiles.

Additives and Flavorings

Cigarette manufacturers may add optional additives and flavorings to enhance the taste, aroma, and burning characteristics of their cigarettes. These additives can include menthol, vanilla, cocoa, or other flavorings. However, it's important to note that some additives may increase the addictiveness or toxicity of cigarettes.

Filter Design

Filters are designed to reduce the intake of certain smoke constituents. The composition, length, density, and design of filters can vary across different cigarette brands, affecting the overall smoking experience and filtration efficiency.

Paper Porosity

The porosity of the cigarette paper influences the amount of air that can flow through the cigarette during smoking. This affects the burn rate, draw resistance, and overall smoking characteristics.

Manufacturing Techniques

The manufacturing process itself, including the use of specific machinery, parameters, and quality control measures, can impact the consistency, density, and quality of cigarettes.

Regulatory Requirements

Different countries and regions have regulations and standards governing the composition and labeling of cigarettes. These regulations may restrict or control the use of certain ingredients, additives, or descriptors on packaging.

It's important to note that while these factors can influence the composition and characteristics of cigarettes, smoking any form of tobacco is harmful to health and can lead to various health issues.

Cigarette making machines are complex and efficient systems designed to automate the production of cigarettes. They consist of various components, including tobacco feeders, garniture tapes, paper supply systems, filter attachments, gluing units, cutting mechanisms, and packaging systems. The process flow of these machines involves tobacco feeding, tobacco rod formation, paper wrapping, filter attachment, gluing, cutting, and packaging. These machines enable the tobacco industry to produce large quantities of cigarettes with consistent quality, meeting the demands of consumers worldwide.